About Me

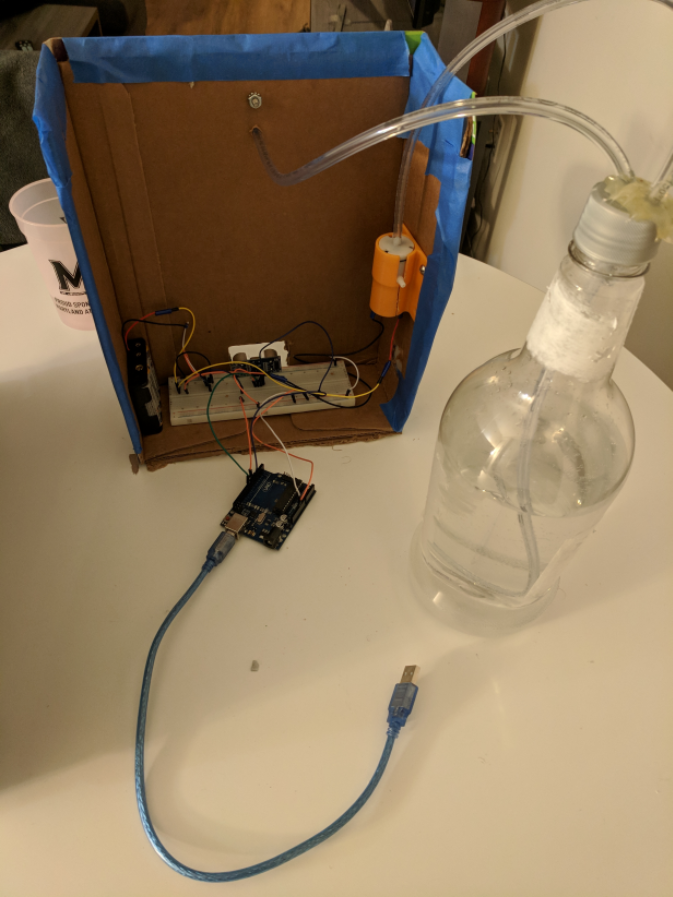

Mechanical Engineer who is focused on product development and innovation. I have experience taking products and projects through the entire product development cycle; from end user needs, to prototypes, engineering analysis, testing, and both high and low volume manufacturing. I am a proud alumni of the University of Maryland's A. James Clark School of Engineering, University Honors Program, and the Quality Enhancement Systems and Teams Honors Program (QUEST). I have a passion for building things, tinkering, voiding warranties and taking things apart.

Contact Details

Drew Hamroff

drewham14@gmail.com